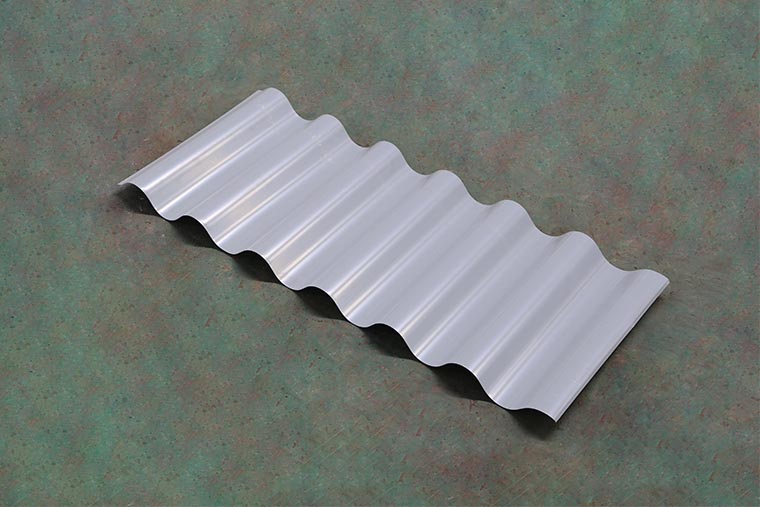

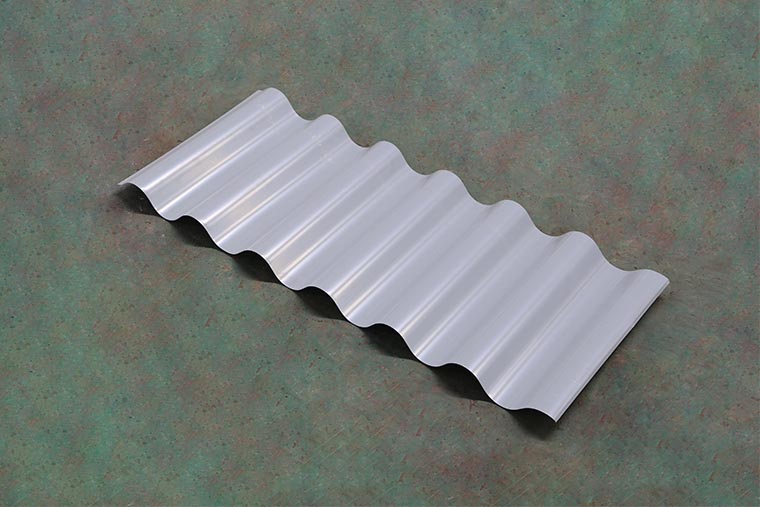

Enhanced Verson YX36.5--780 Corrugated Panel Roll Forming Machine

> Profile

> metal roof panel roll forming machine parameters

1. | Suitable material: | Color steel |

2. | Width of the raw material : | 1000 |

3. | Forming station | 28 steps |

4. | Power : | 5.5kw+2.2kw |

5. | Thickness of the plate: | 0.4-0.8mm |

6. | Productivity: | approx.15-20m/min |

7. | Diameter of the roller: | 75mm |

8. | Weight About: | 8T |

9. | Voltage: | 380V 50Hz 3phase |

10.. | Exit rack | 3meters |

11. | Raw material of the cutter : | Cr12mov |

12. | Raw material of the roller: | Bearing steel |

> Main features of corrugated panel roll forming machine

The advantages of corrugated roof panel forming machine are as

follows:

1.Products widely used in modern factory,such as workshop,4S auto

shop,is a new popular roof panel.

2.Easy operation, low maintenance cost

3.Forming steps: 28

> Detailed Images of corrugated panel forming machine

Machine Parts

1) Corrugated roof panel forming machine rollers

Brand: BMS Original: China

Rollers manufactured from high quality 45# steel, CNC lathes, Heat

Treatment.

With black treatment or Hard-Chrome Coating for options.

With feeding material guide,Body framemade from 300# H type steel

by welding

2) Corrugated roof panel machine touch screen

easy to operate.

3) Corrugated roof panel machine post cutter

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting, use the same hydraulic motor drive

Hydraulic motor: 2.2KW, Hydraulic pressure range: 0-12Mpa

Cutting tool material: Cr12, Heat treatment

4) Corrugated roof panel machine control cabinet

Overlap Effect

5) Corrugated roof panel machine decoiler

Manual Decoiler: one set

Un-powered,manually control steel coil inner bore shrinkage and

stop

Max. feeding width: 1000mm, coil ID range 470mm±30mm

Capacity: Max. 5Ton

With 6 tons hydraulic decoiler for option

6) Corrugated roof panel machine exit rack

Un-powered,three units

> Other detailes of corrugated roof panel roll forming machine

Suitable for material with thickness 0.4-0.8mm

Shafts manufactured from 45#,Main shaft diameter=φ75mm,precision

machined

Motor driving,Gear chain transmission, 28 rollers to form

Main motor=5.5KW , Frequency speed control. Forming speed

approx.15-20m/min

PLC Control System (Touch screenbrand:German Schneider

Electric/Taiwan WEINVIEW,

Inverter brand:Finland VOCAN/Taiwan DELTA/ALPHA,Encoder brand:Japan

Koyo/OMRON)

Combined with: PLC, Inverter, TouchScreen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

User's manual in English